The last three weeks have been spent on the highly unglamorous but absolute necessity of wiring the layout up. Logic dictates building a control panel first which was built in the woodworking shop, commonly known as the garage. Luckily I’d managed to get the component parts for this at Model Rail Scotland having planned ahead, but thinking I could pick more parts and material up at Ally Pally had left everything else. It was only when I’d started the final testing of the panel I realised I was lacking in wire, a 25 pin D connector and a few other bits and pieces, and stuck in the house because of the lockdown.

Its moments like this you realise how much you rely on shows to source the various bits and bats required for layouts, and I’m missing them very much. OK, much the same traders benefited from online orders (mainly Eileens Emporium) but there’s no substitute for browsing through a traders wares and actually physically seeing what you want – quite often I will see something a bit better than what I intended and end up getting that.

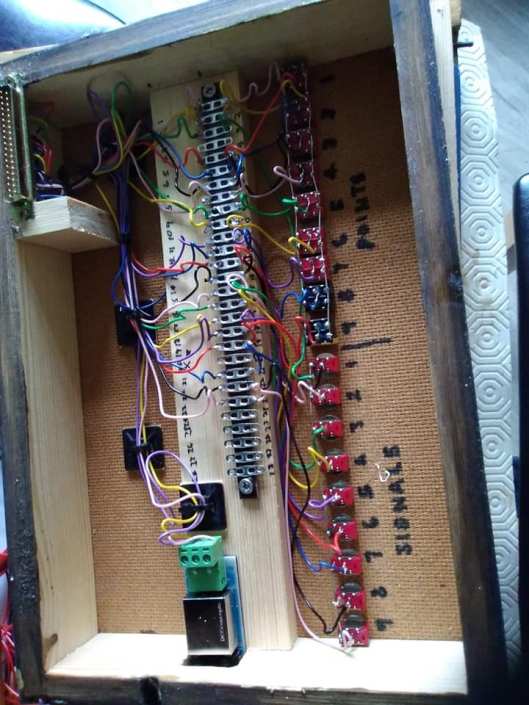

So just over two weeks later I have a wired board. The DCC bus is split into two power districts, the industrial side and the mainline. Point motors are DCC Concepts IP analogue, fed through one of their split power supplies which makes wiring runs a lot easier. Everything was buzzed out with the multimeter as I went along so I was fairkly confident of it working (or most of it) first time.

The wiring was completed a couple of days back and then time spent tidying it all up and securing it before introducing power first to the points. A few needed polarity reversing so that with the lever – or switch in this case – in the normal position, it gives the through route on the panel diagram. Happy all that was well in that camp, the boards were put back into their normal position, connected up, a final check that the points were throwing OK and then plug in the NCE Power Pro and away we go.

OK a class 40 is not the best testing tool for a shunting plank that not likely to see anything much bigger than a 4F or a class 25, but its the only loco to hand which has a chip in it. Its pulled wheels gave a searching test of the points and highlighted a couple of tight spots on crossings but other than that and 3 dry joints on the dropper feeds it was a successful test and bodes well for the future. Next job, put a chip in a far more representative loco!